1 / 1

Details

Hiring Person/CompanyHiring as Company

Company NameJalalsons

Type of AdJob Offer

Salary from40000

Salary to60000

Career LevelExecutive

Salary PeriodMonthly

Position TypeFull-time

Description

Key Responsibilities

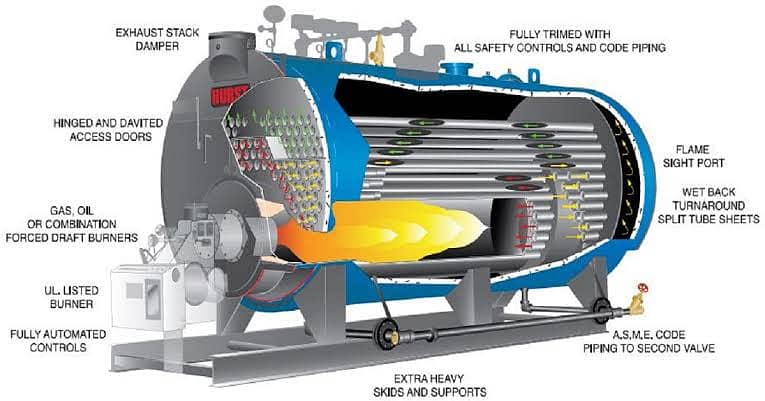

Operation of Boilers: Start up, shut down, and monitor steam boilers according to safety standards and operational guidelines.

Maintenance and Inspection: Regularly inspect boilers and equipment for leaks, wear, corrosion, and other signs of malfunction. Perform routine maintenance tasks such as cleaning, replacing parts, and lubrication.

Monitoring and Control: Continuously monitor water levels, steam pressure, and temperature. Adjust controls to ensure efficient and safe operation.

Record Keeping: Maintain accurate records of operations, repairs, and other relevant information, including hourly or daily logs of temperatures, pressures, and other operational parameters.

Safety Compliance: Follow all safety protocols to prevent accidents and ensure a safe working environment. Regularly test and maintain safety valves, alarms, and other safety devices.

Emergency Management: Act quickly to diagnose issues or malfunctions and take corrective actions in case of emergencies like leaks, equipment failure, or power issues.

Skills Required

Technical Knowledge: Strong understanding of boiler systems, steam production, and the associated control mechanisms.

Mechanical Skills: Ability to perform basic repairs and maintenance on boilers and related equipment.

Attention to Detail: Carefully monitoring readings, controls, and identifying potential issues early.

Safety Awareness: Knowledge of safety procedures for handling steam and pressure systems.

Certifications

In many places, operating a steam boiler requires specific certifications or licenses, such as:

Boiler Operator Certification (requirements vary by state or country).

OSHA Safety Training: Basic safety certification can be beneficial.

This role is essential in industries like manufacturing, power generation, and facilities management, where steam is needed for heating, processing, or generating electricity.

Listed by private user

Ali Murtaza

Member since Mar 2020

See profile

Location

Pakistan

Ad id 1095100390

Report this ad